CEMENT

Cement production is a thermal energy intensive process, which requires heating solid particles up to 1450°C and cooling it down. The process generates hot and CO2 rich exhaust streams. The cement production process, for example, starts with mining of limestone, which is then crushed and ground to powder.

It is then preheated to save energy before being transferred to the kiln, the heart of the process. The kiln is then heated to a high temperature of up to 1480 degrees to convert the material to a molten form called clinker. The clinker is then cooled and ground to a fine powder with other additives and transferred to storage silos for bagging or bulk transportation.

Cement production processes can be categorized as dry, semidry, semiwet, and wet processes depending on the handling of raw material before being fed to the rotary kiln. Nowadays, almost all new plants are based on the dry process and many old wet plants are also remodelled to dry or semidry processes.

Dry cement production mainly involved with high temperature steam use through huge industrial boilers which burn high amount of coal. Those industrial boilers reach very high temperatures thus generates huge amount of hot air and dust. All these hot fluid air and dust are transferred between the processes by pipelines and ducts.

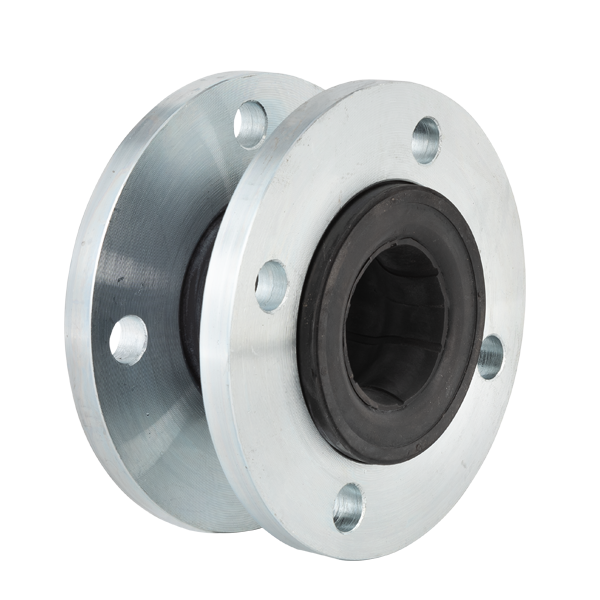

Ayvaz produces circular & rectangular shaped thick wall duct expansion joints (Lens) for the hot air ducts as well as specially designed stainless steel expansion joints for the pipelines of Iron & Steel industry. All welding operations and welding control methods are to be followed carefully and to be monitored by quality control plans.