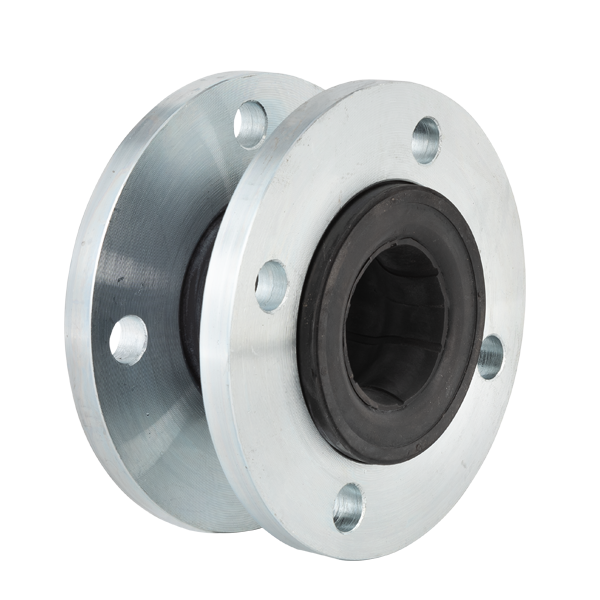

AYVAZ RUBBER EXPANSION JOINTS

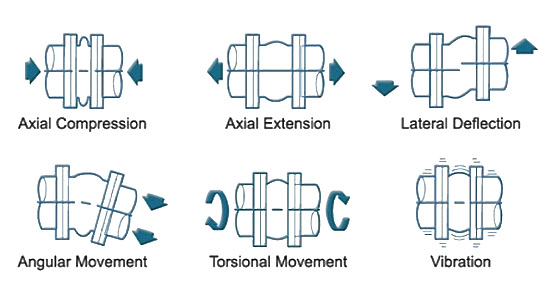

Rubber expansion joint is a flexible connector fabricated of natural and/or synthetic elastomers and fabric, if necessary, internal metallic reinforcements designed to provide stress relief in piping systems due to thermal movements and mechanical vibration.

There are lots of material selection based on usage area of rubber expansion joints. Also rubber expansion joints have advantages and disadvantages between of the metal expansion joints. Rubber expansion joints can absorb large movement in very short distance. They provide all directional movement, such as axial, angular, lateral and torsional that may occur from external conditions. Also reduce wind, shock loading and seismic movements.

APPLICATION AREAS

• Heating and cooling devices

• Materials handling technologies

• Water pipes

• Desalination plants

• Compressors

• Blowers and fans

• Cement industry

• Chemical industry

• Glass industy

• Wood-processing industry

• Pulp and paper industry

• Railed vehicles

• Refineries

• Shipbuilding

• Steel mills

• Sugar industry

ADVANTAGES

Spherical joints have a distinct advantage over metallic expansion joints for corrosive applications and installations requiring a high cycle life. The contour prevents sediment accumulation and creates less turbulence and pressure drop than spool joints. The seal bead eliminates any requirement for gaskets between mating flanges. Spheres may be installed on raised-face or flat-face flanges.

COMPARISON AGAINST METAL EXPANSION JOINTS

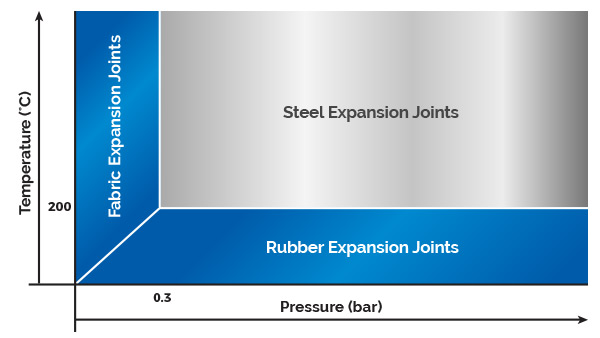

Temperature: Rubber joints with standard construction and materials have an upper range to 110°C. Can be offer special constructions up to 200°C. Metal expansion joints do offer a far greater range, from -250°C to +950°C.

Pressure: Rubber joints depending on diameter, can have pressure capabilities up to 15 bar with a full vacuum rating. Metal joints can be designed for pressures up to 100 bar.

Movements: Rubber and metal expansion joints have similar movement capabilities in the axial plane (compression and extension). However, rubber joints are certainly able to absorb greater lateral movements when compared to metal joints that have similar face to face lengths.

Spring Rates: Rubber and metal joints do have similar characteristics in the axial plane for the standard face to face dimensions. Metal joints are much stiffer when subjected to lateral motion and, typically have a lower lateral movement capability.

Acoustical Impedance: Although well designed (multi-ply) metal joints can lower the transmission of visible vibration, they will continue to transmit distracting and/or damaging noise. Rubber joints significantly reduce the undesirable transmission in piping systems. The elastomeric composition of the joint acts as a dampener that absorbs the greatest percentage of perceptible noise and vibration.

Abrasion/Erosion Resistance: Metal joints typically have a wall thickness anywhere between 0.15mm to 2mm. Rubber joints are much thicker, 12mm to over 25mm. The thin construction of metal joints makes them susceptible to erosive chemicals and abrasive liquids and slurries. Rubber joints are highly resistant to abrasion and erosion of all types and outperform metal joints in the applications where these conditions prevail.

Fatigue/Cycle Life: The fatigue life of a metal joint is affected by many factors such as temperature, pressure, movement, vibration and how the joint was initially designed. Typically, metal joints have a defined cycle or fatigue life that can be calculated through various formulas (EJMA). Metal joints frequently succumb to fatigue failure from excessive cycling/movement. Rubber joints on the other hand are constructed of resilient elastomers and the joint itself acts as a vibration dampener, not susceptible to fatigue/cycle failure.

Installation/Maintenance: Rubber joints do not require additional gasketing and, in many cases, are installed without the use of special handling equipment. Metal joints must be serviced occasionally to insure that the flange gasket is still intact and not deteriorated

MATERIAL SELECTION

Material selection of rubber expansion joints are very variable and depends on the pressure, temperature, fluid etc. parameters. The common materials are, EPDM, IIR, NBR, PTFE and combined with these materials depends of usage area. Also the inner tube and outer tube’s diameter can be different depends of design conditions.

| Table I: Maximum Temperature Ratings | |||||||

| Reinforcing Fabric | Tube or Cover Elastomer | ||||||

| Pure Gum Rubber | Neoprene | Butyl | Nitrile | Hypalon® | EPDM | FKM | |

| Nylon | 180 °F / 82 °C | 225 °F / 107 °C | 250 °F / 121 °C | 210 °F / 99 °C | 250 °F / 121 °C | 250 °F / 121 °C | 250 °F / 121 °C |

| Polyester | 180 °F / 82 °C | 225 °F / 107 °C | 250 °F / 121 °C | 210 °F / 99 °C | 250 °F / 121 °C | 250 °F / 121 °C | 250 °F / 121 °C |

| Aramid | 180 °F / 82 °C | 225 °F / 107 °C | 300 °F / 149 °C | 210 °F / 99 °C | 250 °F / 121 °C | 300 °F / 149 °C | 400 °F / 204 °C |

| Table II. List of Elastomers Used in Expansion Joints and Rubber Pipes | ||||||||||

| MATERIAL DESIGNATION |

RATING SCORE CODE | ELASTOMER PHYSICAL AND CHEMICAL PROPERTIES COMPARISON | ||||||||

| ANSI/ASTM D1418-77 |

ASTM-D-2000 D1418-77 |

7-Outstanding 6-Excellent 5-Very Good 4-Good 3-Fair to Good 2-Fair 1-Poor to Fair 0-Poor X-Contact Mfg. |

ALKALI, CONC. ANIMAL VEG. OIL CHEMICAL WATER |

OXYGENATED HYDRO. LACQUERS OIL & GASOLINE ALKALI, DILUTE |

ACID DILUTE ACID, CONC. ALPHATIC HYDRO AROMATIC HYDRO |

ELE. INSULATION WATER ABSORP RADIATION SWELLING IN OIL |

REBOUND-COLD COMP. SET TENSILE STRENGTH DIELECTRIC STR. |

ABRASION IMPERMEABILITY DYNAMIC REBOUND-HOT |

HEAT COLD FLAME TEAR |

OZONE WEATHER SUNLIGHT OXIDATION |

| COMMON NAME CHEMICAL GROUP NAME |

||||||||||

| CR | BC BE | NEOPRENE CHLOROPENE |

4 3 4 0 | 4 4 0 1 | 2 3 4 6 | 4 5 4 3 | 5 4 2 4 | 5 2 4 5 | 4 4 4 4 | 5 5 6 5 |

| NR | AA | GUM RUBBER POLYISOPRENE, SYNTHETIC |

5 3 X X | X 0 0 4 | 0 0 3 3 | 0 6 5 5 | 6 6 4 6 | 6 6 2 7 | 5 0 5 2 | 4 0 2 0 |

| IR | AA | NATURAL RUBBER POLYISOPRENE, SYNTHETIC |

5 3 X X | X 0 0 4 | 0 0 3 3 | 0 6 5 5 | 6 6 4 6 | 6 2 2 6 | 5 0 5 2 | 4 0 2 0 |

| IIR | AA | BUTYL ISOBUTENE-ISOPRENE |

5 6 5 4 | 4 0 3 4 | 0 0 4 6 | 0 4 5 5 | 4 3 0 | 5 2 6 4 | 4 0 4 5 | 6 5 5 6 |

| FKM | HK | FLUOROCARBON ELASTOMER |

5 6 6 0 | 4 6 1 0 | 6 6 6 5 | 6 5 5 3 | 5 5 6 2 | 4 5 5 5 | 2 6 2 7 | 7 7 7 7 |

| EPR | BA CA DA | EPDM ETHYLENE-PROPYLENE- DIENE-TERPOLYMER |

5 6 5 6 | 6 0 3 6 | 0 0 4 6 | 0 7 6 6 | 7 5 4 6 | 6 5 4 5 | 4 0 5 6 | 6 7 6 7 |

| AFMU | PTFE/TFE/FEP FLUORO-ETHYLENE- POLYYMERS |

7 7 7 7 | 7 7 7 7 | 7 7 7 7 | 7 3 7 X | X X X X | X X X 4 | X X X 7 | 7 7 7 7 | |

| SI | GE | SILICONE | 5 5 5 0 | 2 X 0 2 | 0 0 2 6 | 2 5 6 6 | 4 0 3 6 | 6 0 2 0 | 2 2 6 7 | 6 6 6 6 |

TYPES OF RUBBER EXPANSION JOINTS

ARCH TYPE:

A full face integral flange design is available in both Single Arch and Multiple Arch Types.

Single Narrow Arch Type:

Construction is of fabric and rubber, reinforced with metal rings or wire. The full face flanges are integral with the body of the joint and drilled to conform to the bolt pattern of the companion metal flanges of the pipeline.

This type of rubber face flange is of sufficient thickness to forma tight seal against the metal flanges without the use of gaskets.

Multiple Narrow Arch Type:

Joints with two or more arches may be manufactured to accommodate movements greater than those of which a Single Arch Type joint is capable.

Multiple Arch joints of most manufacturers are composites of standard sized arches and are capable of movements of a single arch multiplied by the number of arches.

PTFE Lined

Spool Arch Type joints are available in many standard pipe sizes with Fluoroplastic liners of TFE and/or FEP. These liners are fabricated as an integral part of the expansion joint during manufacture and cover all wetted surfaces in the tube and flange areas. Fluoroplastic provides exceptional resistance to almost all chemicals within the temperature range of the expansion joint body construction.

Non-metallic Reinforced Design

Constructed similar to the Spool “Arch” Type except the carcass does not contain wire or metal ring reinforcement. Pressure resistance is accomplished through the use of special external flanged retaining rings furnished with the joint.

Reducer Type

Reducing expansion joints are used to connect piping of unequal diameters. They may be manufactured as a concentric reducer with the axis of each end concentric with each other or as an eccentric reducer having the axis of each end offset from each other. Tapers in excess of 20 degrees are not desirable.

Sleeved Arch Type

This joint is similar to the “Arch”typeexcept that the capped sleeve ends have an I.D. dimension equal to the O.D. of the pipe. These joints are designed to slip over the straight ends of the open pipe and be held securely in place with clamps. This type of joint is recommended only for low to medium pressure and vacuum service because of the difficulty of obtaining adequate clamp