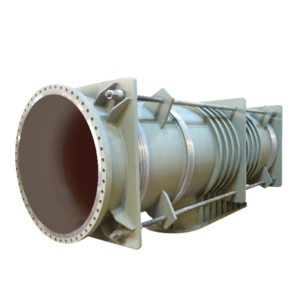

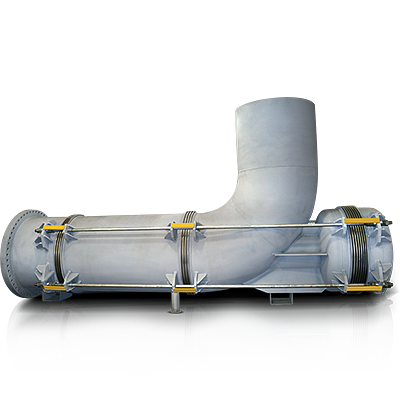

ÖZEL KOMPANSATÖRLER

Özel kompansatörlerin körükleri EJMA koduna göre tasarlanmıştır. Yüksek basınç uygulamaları için çok katmanlı körükler ayrıca takviye ve dengeleme halkalarına sahip körükler de mümkündür.

Akışkanın cinsi, hareket değerleri (eksenel, yanal, açısal), çalışma sıcaklığı ve basıncı gibi özelliklere göre körük malzemesinin kullanım ömrü de özelleştirilebilmektedir.

ÜRETİM

Kompansatörler basınçlı ekipmanların borulama sisteminin parçalarıdır. Bu bağlamda Avrupa basınçlı ekipman direktifine (PED 2014/68/EU) ve ayrıca borulama prosesine ilişkin Amerikan Ulusal Standardı ASME Bölüm VIII Div.'ye göre tasarlanmış ve üretilmiştir. 1&2, ASME B 31.3.

Borular, kapaklar, flanşlar, rot kolları vb. gibi kompansatörlerin tüm bileşenleri boru gerilim analizi ile kontrol edilir, böylece malzeme tipini seçmemize olanak sağlanır.

AYVAZ ÖZEL KOMPANSATÖR KAPASİTE ARALIĞI

DN15-6000

ÇAP

150 bar

150 BAR'A KADAR (ÇAP VE SICAKLIĞA BAĞLI OLARAK)

900 °C

TASARIM SICAKLIĞI (MALZEME SEÇİMİ)

16 ton

VİNÇ KAPASİTESİ

PED 2014/68/EU&ASME U STAMP-U2 STAMP

Kompansatörler, basınçlı ekipmanların parçalarıdır; bu bağlamda PED 2014/68/EU&ASME U Stamp-U2 Stamp'e göre tasarlanıp üretilmektedir.

ÜRETİM TESTLERİ

• Hidrostatik Basınç: Kompansatörler tasarım basıncının 1,5 katı hidrostatik basınca maruz kalır.

• Vakum Testi: Tam vakum uygulamaları için 760 Hg/mm'de vakum testi de uygulanabilir.

• Gaz Kaçağı Tespiti: Uygun sızdırmazlık için helyum ile gaz kaçağı tespiti tavsiye edilir.

KAYNAK

Standart kompansatörlerin yapımına yönelik tüm kaynak işlemleri isteğe bağlı olarak Avrupa normlarına veya ASME standartlarına göre tamamlanmaktadır.

• WPS, EN 15609-1'e göre verilir

• PQR, EN 15614-1'e göre verilir

• Kaynakçı Sertifikası EN ISO 9606-1

• Kaynak Operatörleri EN ISO 14732

• ASME Bölüm IX

NDT KONTROLLERİ

Kaynak kontrollerine yönelik tahribatsız testler, TÜV akredite üçüncü taraf denetçiler tarafından kurum içinde tamamlanır. Aşağıdaki kontroller ve standartlar geçerlidir.

• EN3452-1, EN23277'ye göre %100 PT

• EN17638'e göre %100 MT

• Köşe kaynakları için %100 VT

• %100 RT, EN17638'e göre EN ISO 10675-1, EN I7636

• %100UT, uyarınca. EN 17640, EN 11666'ya göre

AYVAZ ÖZEL KOMPANSATÖRLER

Ayvaz, ihtiyaçlarınıza göre özelleştirilebilen farklı tiplerde özel kompansatörler sunmaktadır.

TALEP FORMU

Ürün isteklerinizi bize iletmek için talep formunu doldurun, size en kısa sürede geri dönelim.