Self-Checking High Water Level Controller

Regarding the operation and the controlling of the boilers, rules and regulations are subject to change due to country's applications. Nevertheless, it is clearly shown in the regulations that boilers should be operated safely without the assistance of a person when there is high-safety concern.To set high or low water level of a boiler, the design condition should be carefully inspected. Any amount above or below design limit of boiler may lead to dangerous events or inefficient working operations. These are the possible deficiencies of uncontrolled high water level:

• The transfer of water to steam may cause in malfunctioning due to dirt and / or failure of the steam system components (valve, pipe, system, process, etc.).

• Wet and dirty steam may contaminate or disrupt the produced steam. Wet steam may increase the water film thickness which may reduce the heat transfer, eventually may result in lower processing temperatures. This will cause low efficiency, increase in process duration and unit cost.

Overfilled boiler may cause splash, damage in process and injuries of people.

With all above deficiencies, below results may occur.

Poor quality steam production, lower production rates, poor product quality. Increased maintenance cost of plant and components, damage to steam systems, possible personnel injuries

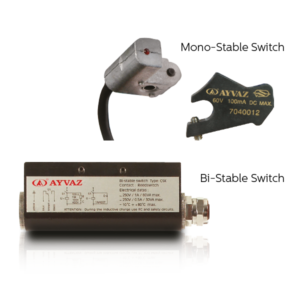

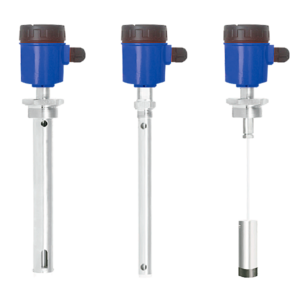

To prevent all these possible deficiencies, high level water controller should be used to control the water pump, shutting-off burner, switching off supply water valve and giving alarm to warn personnels.

Taken precautions can vary by the requirements of facilities.

Documents

Inquiry Form

Please send us your inquiry using our contact form and we will contact you immediately.