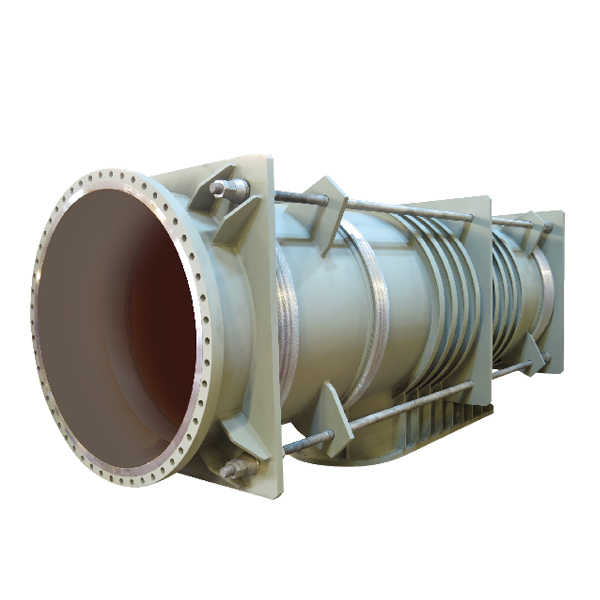

Thick Wall Expansion Joints (Lens)

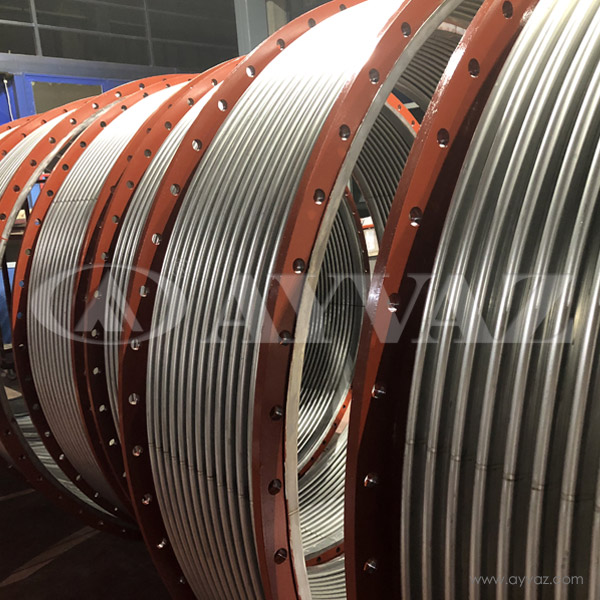

Lens type of metallic expansion joint is a flexible piping element that consists of a single corrugation bellows generally as thick as the mating system material with welding end connections. They are usually used for compensating only axial movements. These expansion joints are characterized by a high convolution profile and thick ply construction which is constructed by welding.

Thick wall expansion joints are used in large power plants, gas and oil and chemistry industries where the long life-cycle of the expansion joint is very important. Thick-walled bellows are invariably used in the shell of fixed tube sheet exchangers and are fabricated from a plate of the same material and thickness as the shell barrel.

CONSTRUCTION

Expansion Joints are the parts of pip¬ing system of pressurized equip¬ment. In this respect construction of the expansion joints are designed and produced according to European pressurized equipment directive (PED 2014/68/EU) as well as American Nation¬al Standard for piping process ASME Section VIII Div 1&2, ASME B 31.3.

All components of the expansion joints like, pipes, caps, flanges, tie rods etc… are checked by piping stress ana¬lysis thus enable us to se¬lect material type & thickness accord¬ing to permissible stress values.

GENERAL CAPABILITY RANGE FOR AYVAZ EXPANSION JOINTS

• Dimension: DN 15-6000

• Design pressure: Up to 150 bar (de¬pending on the diameter and tem¬perature)

• Lifting capacity: Up to 16 ton

TEST&CERTIFICATION

• Expansion Joints are the parts of piping system of pressurized equipment in this respect construction of the expansion joints are designed and produced according to PED 2014/68/EU&ASME U Stamp-U2 Stamp.

• Expansion joints are exposed to hydrostatic pressure at 1,5 times of design pressure.

• For full vacuum applications, vacuum test at 760 Hg/mm is also applicable.

• Additionally, gas leakage detection with helium is advised for proper tightness.

WELDING

All welding operations for the construction of expansion joints are completed according to European norms or ASME standards optionally.

• WPS are issued acc.to EN 15609-1

• PQR are issued acc.to EN 15614-1

• Welders Certificate EN ISO 9606-1

• Welding Operators EN ISO 14732

• ASME Section IX

NDT CONTROLS

• Non-destructive testing for welding controls are completed in house by the TÜV accredited third party inspectors. Following controls and standards are applicable.

• 100% PT acc.to EN3452-1, EN23277

• 100% MT acc.to EN17638

• 100% VT for Fillet welds

• 100% RT acc.to EN ISO 10675-1, EN I7636

• 100% UT acc. to EN 17640, EN 11666