FCCU Expansion Joints

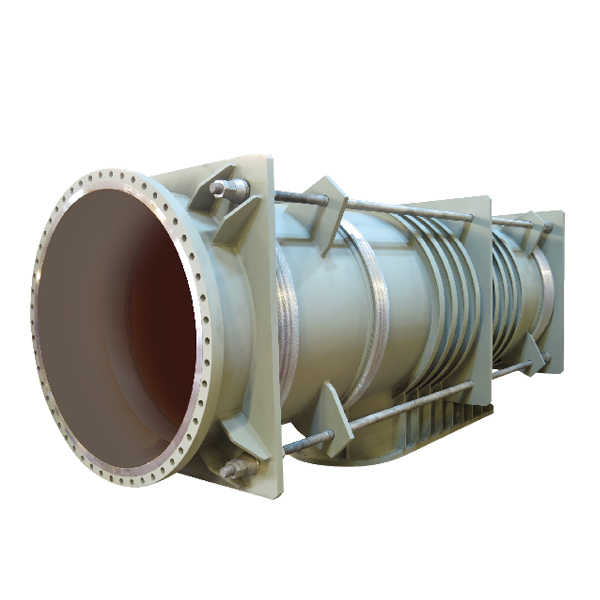

In Oil Refinery industry, the FCCU is the most important and critical unit for its main function is to convert heavy distillates into lighter ones (gasoline and diesel), improving the yield and efficiency of the refining processes. In general FCCU expansion joints are divided into 2 types: HOT wall and COLD wall.

Cold Wall expansion joints are refractory lined to ensure the outside wall temperature does not exceed the maximum. The wall is made from stainless steels and the lining is designed inside of the expansion joint. Hot Wall expansion joints are designed with the refractory lining on the inside as a thermal barrier. The purpose of the lining is to withstand abrasion from the catalyst flow medium.

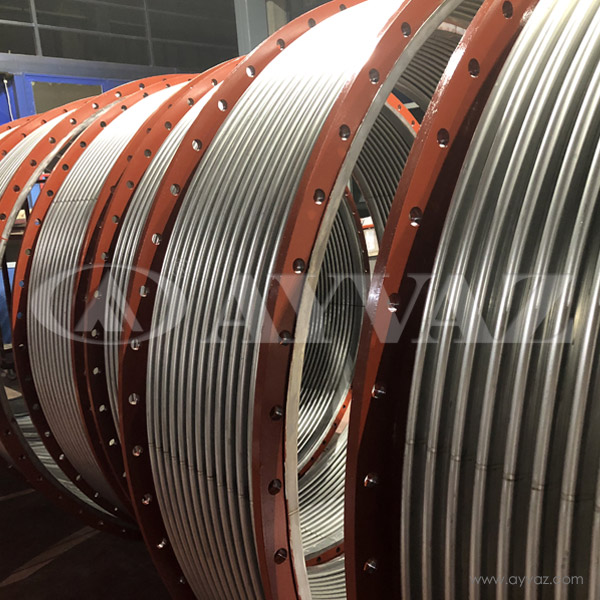

The expansion joint is a key component in this application because of critical operating conditions, and the selection of bellows material is very important. Double ply or redundant ply bellows are commonly utilized for FCCU applications. The simple double ply bellows utilizes the strength of both plies to withstand the operation conditions, and the redundant ply bellows are designed to let each ply take up the full load. So, if the inner ply is leaking, the outer ply will be able to take up the load and continuously operate without failure.

APPLICATIONS

• Petrochemical industry

• Refining technology

• Chemical industry

• Process industry

• Hydrocarbon gases

• FCCU applications with carbon steel (lower temperature) piping

• Petrochemical applications with large movements, high process tempera- tures and carbon steel (lower temperature) piping

• Applications with large movements, high internal temperatures and carbon steel piping

BELLOWS DESIGN

Bellows of FCCU expansion joints are designed according to EJMA 10 code. For high pressure applications multi layered bellows with reinforcing rings. According to the requested features like type of transported media, spring rate values (axial, lateral, angular) or operation temperature, pressure & life cycle bellows material could be customized.

CONSTRUCTION

Expansion Joints are the parts of pip¬ing system of pressurized equip¬ment. In this respect construction of the expansion joints are designed and produced according to European pressurized equipment directive (PED 2014/68/EU) as well as American Nation¬al Standard for piping process ASME Section VIII Div 1&2, ASME B 31.3.

All components of the expansion joints like, pipes, caps, flanges, tie rods etc… are checked by piping stress ana¬lysis thus enable us to se¬lect material type & thickness accord¬ing to permissible stress values

GENERAL CAPABILITY RANGE FOR AYVAZ EXPANSION JOINTS

• Dimension: DN 15-6000

• Design pressure: Up to 150 bar (de¬pending on the diameter and tem¬perature)

• Lifting capacity: Up to 16 ton

TEST&CERTIFICATION

• Expansion Joints are the parts of piping system of pressurized equipment in this respect construction of the expansion joints are designed and produced according to PED 2014/68/EU&ASME U Stamp-U2 Stamp.

• Expansion joints are exposed to hydrostatic pressure at 1,5 times of design pressure.

• For full vacuum applications, vacuum test at 760 Hg/mm is also applicable.

• Additionally, gas leakage detection with helium is advised for proper tightness.