Feeding The Distribution System With Multiple Boilers

When the distribution system is supplied with more than one boiler, the design of the installation is critical. One of the important criteria here is the pressure drops that can occur in the pipes running from the steam boiler to the steam lines. If the pressure drops between all the steam boilers are equal, the demand for loads and peak traction shall be shared equally.

If there is a significant difference between the pressure drops in the steam boilers, most of the possible loading and sudden steam demands will fall on a single boiler. this single boiler cannot lift the whole load and can cause water to drift. Depending on the water entrainment of the bogie, when water is lost, cold water is supplied to the boiler to supply. Due to the cold water, there is a temperature drop in the boiler. this may halt the operation of the boiler. After the overloaded boiler has lost its function, the same process will be experienced in other boilers.

| Boiler Equipment Standart Size | |||||||||||

| Steam Capacity | Feed Pump Velocity | Main Steam Valve ( Mk-16) | Safety Valve | Feed Water Inlet | Feed Pump Inlet | Air Drain Valve | Blow Down Valve | ||||

| 6 ATU | 8 ATU | 10 ATU | 12 ATU | 6 ATU | 8 ATU | ||||||

| kg/h | T/h | DN | DN | DN | DN | DN | DN | DN | DN | DN | DN/PN |

| 400 | 0,7 | 40 | 40 | 32 | 32 | 25 | 25 | 25 | 32 | 15 | 40/25 |

| 600 | 1 | 50 | 50 | 40 | 40 | 25 | 25 | 25 | 32 | 15 | 40/25 |

| 800 | 1,3 | 50 | 50 | 40 | 40 | 25 | 25 | 32 | 40 | 15 | 40/25 |

| 1000 | 2 | 65 | 65 | 50 | 50 | 25 | 25 | 32 | 40 | 15 | 40/25 |

| 1200 | 2 | 65 | 65 | 50 | 50 | 32 | 25 | 32 | 40 | 15 | 40/25 |

| 1400 | 2,3 | 65 | 65 | 50 | 50 | 32 | 25 | 32 | 40 | 15 | 40/25 |

| 1500 | 2,5 | 80 | 80 | 65 | 65 | 32 | 32 | 32 | 40 | 15 | 40/25 |

| 2000 | 3,6 | 80 | 80 | 65 | 65 | 40 | 32 | 32 | 40 | 15 | 40/25 |

| 2400 | 4 | 100 | 100 | 80 | 80 | 40 | 32 | 32 | 40 | 15 | 40/25 |

| 3000 | 5 | 100 | 100 | 80 | 80 | 50 | 40 | 32 | 40 | 15 | 40/25 |

| 3600 | 6 | 125 | 100 | 100 | 80 | 50 | 40 | 32 | 40 | 15 | 40/25 |

| 4000 | 6,4 | 125 | 125 | 100 | 100 | 65 | 50 | 32 | 50 | 15 | 40/25 |

| 4600 | 8 | 150 | 125 | 125 | 100 | 65 | 50 | 32 | 50 | 20 | 40/25 |

| 5000 | 10 | 150 | 150 | 125 | 125 | 80 | 65 | 40 | 65 | 20 | 40/25 |

| 7000 | 11 | 150 | 150 | 125 | 125 | 80 | 65 | 50 | 65 | 20 | 40/25 |

| 8000 | 13 | 200 | 150 | 150 | 125 | 80 | 80 | 50 | 65 | 20 | 40/25 |

| 9000 | 15 | 200 | 150 | 150 | 150 | 80 | 80 | 50 | 80 | 20 | 40/25 |

| 10000 | 16 | 200 | 200 | 150 | 150 | 100 | 80 | 65 | 80 | 20 | 40/25 |

The steam boiler must be large enough to meet the required load. If too large, the efficiency will be lower and the installation costs will be higher. In cases where a single boiler operates at full capacity, the establishment of a second boiler will be a rational solution to meet the possible needs of the main boiler in which the production peaks and the system load increases.

Boiler Applications

There are two main types of boilers: flame smoke tube boilers and water tube boilers.

Flame smoke tube boilers are the most commonly used type of boiler in the steam industry. With their economy, operating pressures and steam production capacities are sufficient for many industrial applications.

Water tube boilers are used in power generation turbines where high pressure is required and high steam flow rate is required.

A steam boiler should be designed according to the desired pressure and steam capacity.

Ayvaz Hygenic Steam Generator Applications

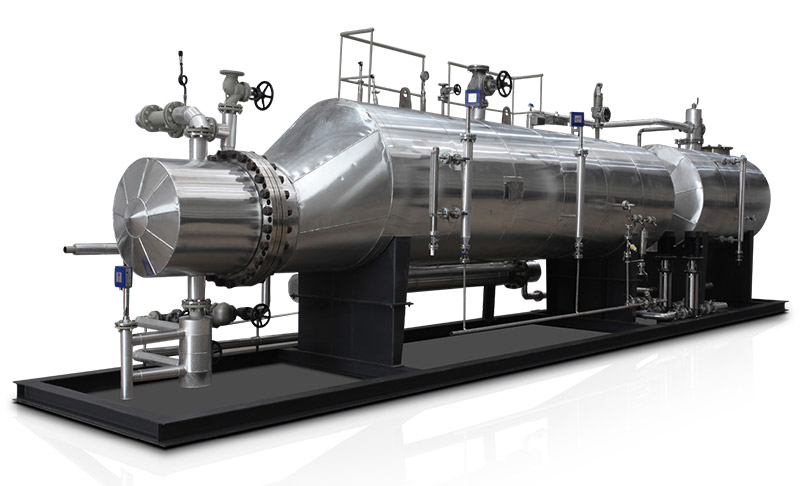

HYGIENIC STEAM / PURE STEAM GENERATOR

Today, there are four steam grades commonly used in the industry:

System (Plant) Steam, The Filtered Steam, Hygienic Steam, Pure Steam.

System is perfect for heat transfer application for petrochemicals, pulp mill and paper industries. Food companies should use filtered steam at a minimum level or use hygienic steam to remove the risk of contamination. Pure steam is the highest grade choice and is required for pharmaceutical and biotechnological applications. Hygienically and pure steam; It is used for sterilization, vacuuming, humidification and heating processes in Food, Pharmaceutical, Cosmetic and Hospital establishments. Since steam used in these processes must meet the hygiene norms, Hygienically Steam Generation is provided by Sekonder Hygienically Steam Generators which are suitable for sterile steam conditions.

| Steam Purity Range | Steam Application Area |

| Pure | Pharmaceutical Industry |

| Biotechnology | |

|

Clean |

Hospital |

| Cosmetic | |

| Food&Beer | |

| Filtered | Food&Beer |

|

Plant |

Hvac |

| Textile | |

| Petrochemical |

HYGIENIC STEAM

When “Steam Cleaning” is mentioned, it is often referred to as “Hygienic Steam” rather than system steam.

This is usually divided into 4 different categories:

System Steam - FDA approved standard boiler chemicals are used in a typical conventional water treatment and inside the steam generated boiler. The tubing is standard carbon steel or even black pipe can be cast iron. All the condensate is recovered.

Filtered Steam - Steam, which is generated by conventional boiler, is filtered to remove condensate and solid particles. FDA approved chemicals used in standard boilers. If the pipe is a standard carbon steel or black iron, it must be replaced with 316 Stainless Steel. All the condensate is recovered.

Hygienic Steam - is not include any addiction (boiler chemicals etc.) and iyonized or produced by reverse osmosis systems. All materials, components and pipes are 316 L Stainless Steel. Rarely recovered condensate is typically sent to a settling tank and then it is for water purification.

Pure Water - is not include any addiction (boiler chemicals etc.) and which is production of pure water. All materials, components and pipes are 316 L Stainless Steel.