Steam traps and valves require periodic maintenance, easily applicable and removable jacket type insulations are more appropriate rather than fixed insulation applications for these armatures. A valve jacket is a simple and smart solution for preventing heat losses around the valves at hot or cold liquid transporting pipelines.

Thermal energy benefit by jacket type insulations is dependent on some factors likewise process temperature, ambient temperature and wind speed. Un-insulated valves cause energy loses, reducing energy loses to the minimum level by using valve jackets helps to reduce operation costs. Easily removable valve jackets make the maintenance easier.

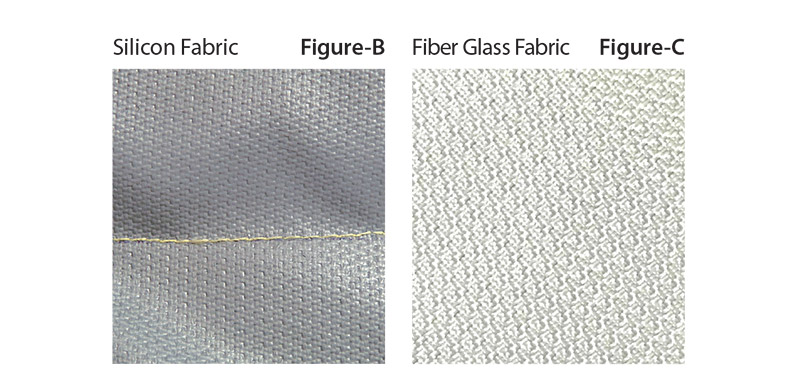

FABRIC TYPES

There are many kind of fabrics that use for insulation; Aerogel, rockwool, glass wool, ceramic fibre, PVC foam, calcium silicate, expanded perlite etc. These are the common use material that you can find below.

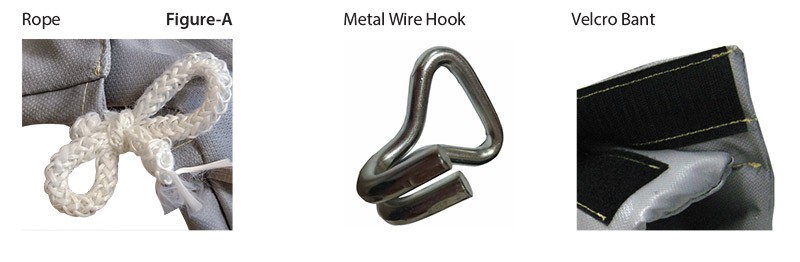

JACKET FABRIC

Figure A - Ceramic fabric with 1260 °C resistance.

Figure B - Outer layer is Silicon Fabric with 200 °C resistance; inner layer is opt. for low temperatures.

Figure C - Inner layer is Fiber Glass Fabric with 500 °C Resistance.

COVER MATERIALS

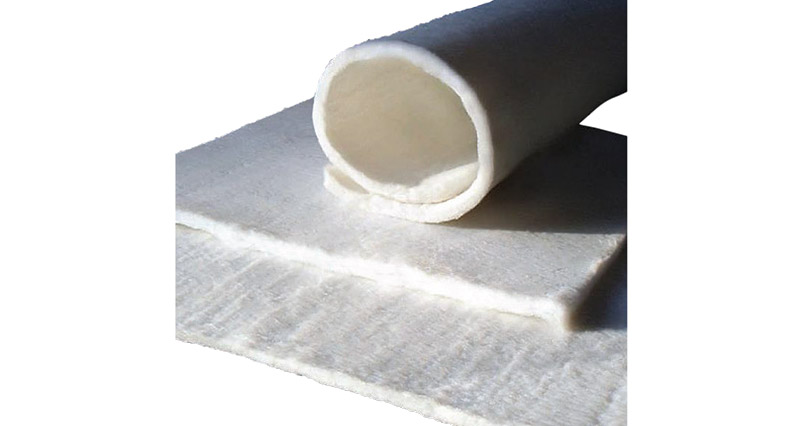

INSULATION MATERIALS

ROCK WOOL

• It is obtained by making the basalt stone melt and fibrous.

• The thermal conductivity value k= 0,040 W/m-K.

• The water vapor diffusion resistance is m= 542 mgm/Nh Mu (μ)

• Rockwool is also an open-pored material. 99% of the material covers the air gap. In this respect, it is easy to get wet if measures are not taken.

PYROGEL XT

• Thickness: 5 mm - 10 mm

• Max Usage Temperature: 0 °C + 650 °C

• The thermal conductivity value k = 0.021 W / m-K.

• Color: Beige

• Density: 0.15 g / cc

• Hydrophobic: Yes

• It has 3-5 times better k value than other insulation materials.

• It is resistant to pressure and impact.

• According to ISO 1182:1990 flammability is Passed.

• Fire performance reaction according to BS EN 13501-1: 2007 is A2 passed

CRYOGEL X

• Thickness: 5 mm - 10 mm

• Max Usage Temperature: -200 °C + 90 °C

• The thermal conductivity is k = 0.015 W / m-K.

• Color: White

• Density: 0.15 g / cc

• Hydrophobic: Yes

• It has 3-5 times better k value than other insulation materials.

• It is resistant to pressure and impact.

• According to ISO 1182:1990 flammability is Passed.

• Fire performance reaction according to BS EN 13501-1: 2007 is A2 passed

SELECTION CRITERIA

• Resistance to Different Operating Temperatures: Protects physical and thermal properties.

• Physical Strength: It should not lose its original properties during (vibration), storage, loadings, operation and application.

• Mechanical Strength: should not deteriorate in expansion and contraction.

• It must be easy to install.

• Resistance to Flammability: must be considered and covered with appropriate coating techniques.

• Resistance to Corrosive Effects: Water, steam etc. resistance to leaks or condensation.

• Insulation Thickness and Weight: Investment cost should be observed.

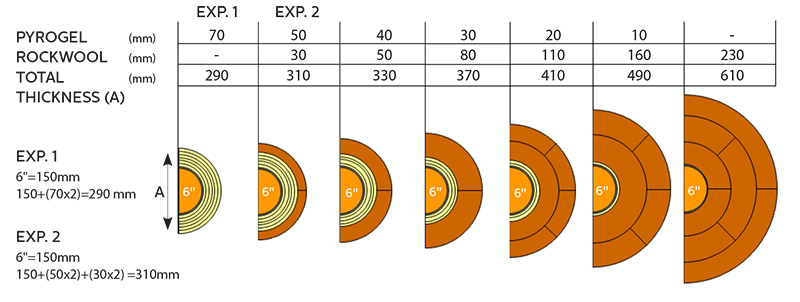

COMBINATION OF ROCKWOOL AND AEROGEL

• Combined use reduces surface area.

• Aerogel can be use at high temperatures.

• Rockwool can be use at low temperatures.

• It also reduces the installation cost.

• At temperatures above 175 °C, rockwool is damaged and the insulation quality is reduced.

• Combined use will also increase the lifetime and thermal resistance capacity of the line.

INSULATION ADVANTAGES

• Healthy materials keeps safe from burn injuries

• Heat economy >> Energy, competition, business advantages

• Providing thermal comfort conditions

• Sound insulation

• Fire protection

• Prevent from sweating, humidty, evaporation and frost

• Prevents the temperature drop in pipelines, provides using of thermal capacity efficiently

COMBINED APPLICATION EXAMPLE

In this example, Pipe Size is 6", Pipe Inlet Temperature Tin = 550 °C, Ambient Temperature TAMB= 20 °C and insulation surface temperature TSRF= 40 °C.

STANDARD OF THERMAL HEAT UNIT (R)

| Insulation Scale | 50 mm Rockwool | 10 mm Pyrogel | 10 mm Pyrogel + 50 mm Rockwool | 20 mm Pyrogel + 50 mm Rockwool | 30 mm Pyrogel + 50 mm Rockwool |

| R Unit Value* | 1,428 m2.K/W | 0,476 m2.K/W | 1,904 m2.K/W | 2,380 m2.K/W | 2,856 m2.K/W |

*R value calculation: Insulation Thickness (mm) / Thermal Conductivity (k).