BELLOWS DESIGN

OUR DESIGN SOFTWARE

Ayvaz developed its own design software which is based on the requirements of EJMA (Expansion joint manufacturer’s association) latest edition 10th.

EN 14917:2012 STANDARD

Apart from the EJMA coding, we also follow EN 14917:2012 standard for design of the bellows and construction of the Expansion joints. Ayvaz also takes place at European technical committee meetings organized by CEN for updating EN14917:2012 standard.

ASME REQUIREMENTS

For American projects, we follow the ASME requirements, we can design metal bellows acc.to ASME Section VIII, division 1, appendix 26. Construction according to ASME Section VIII, division 2 and B31.3 is also what we are familiar with.

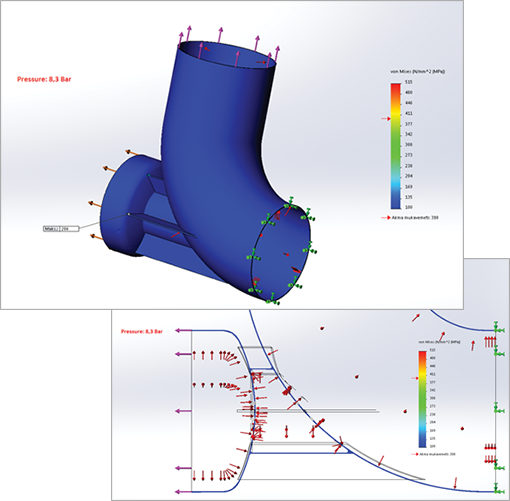

STRESS ANALYSIS

• Ayvaz uses latest stress and deformation analysis to observe the capabilities such as buckling and inflation of the general expansion joint constructions and component including, pipes, flanges, tie rods and bellows.

• Positive pressure and vacuum conditions: We do all analysis for both positive pressure (test conditions) and full vacuum conditions (if necessary) to complete the construction analysis.

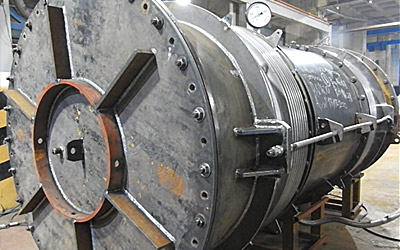

TEST & CERTIFICATION

• Expansion Joints are the parts of piping system of pressurized equipment in this respect construction of the expansion joints are designed and produced according to PED 2014/68/EU&ASME U Stamp-U2 Stamp.

• Expansion joints are exposed to hydrostatic pressure at 1,5 times of design pressure.

• For full vacuum applications, vacuum test at 760 Hg/mm is also applicable.

• Additionally, gas leakage detection with helium is advised for proper tightness.

Hydrostatic Pressure Test

Hydrostatic Pressure Test