Trace-Flex Hose

It is essential to keep the temperature of the special fluids transported in very long pipelines at certain temperature levels, especially in chemical and petro-chemical processing plants and refineries.

Heat tracing systems are specially designed and developed to protect the industrial plants and the fluids flow through the pipelines against the temperature losses and even the freezing, depending on the external temperatures. By heat tracing, it is possible to maintain the right viscosity and to prevent the unrequired flow resistances.

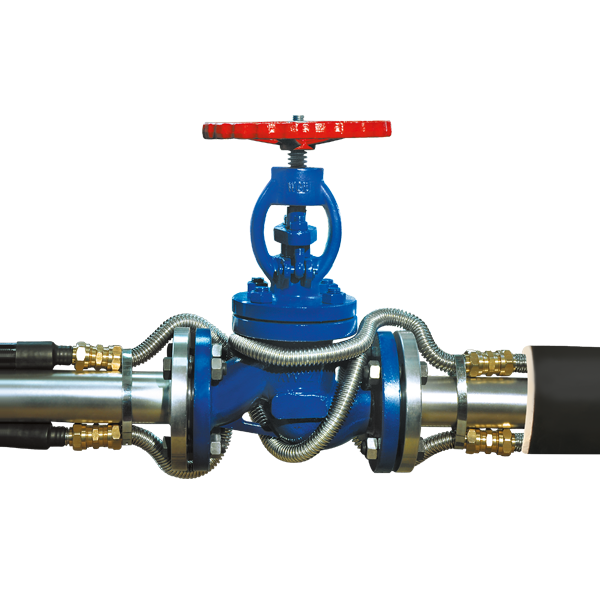

Classic heat tracing is done by the rigid copper or stainless steel pipes that extend along with the main pipeline and heat the pipes or connections around the critical points by the high temperature fluids carried through.

USING STAINLESS STEEL HOSES IN HEAT TRACING (TRACEFLEX)

The success of the heat tracing is highly dependent on the heat transfer from the tracing line to the main pipeline in a limited time. Accordingly, using metal hoses with low wall thickness and high effective surface which is provided by the corrugated structure, in heat tracing increases the success and the reliability of the system.

Meanwhile, the flexibility of the metal hose assemblies and the installation features with no need for additional fittings or connection parts in the direction chances make the assembly easier and reduce the labouring and installation costs remarkably.