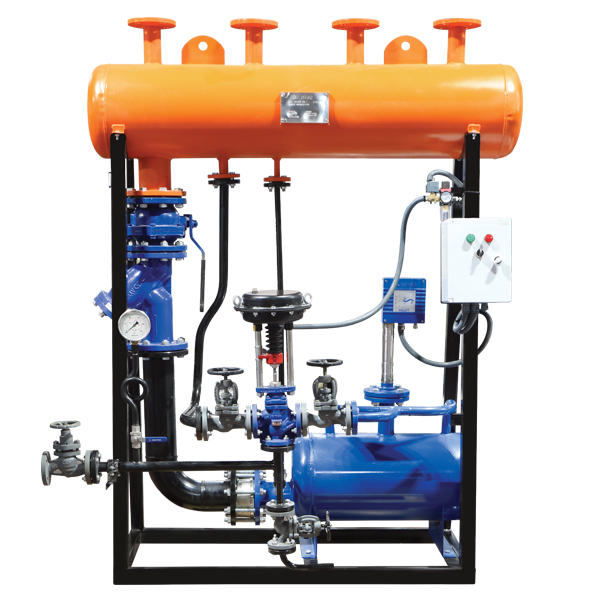

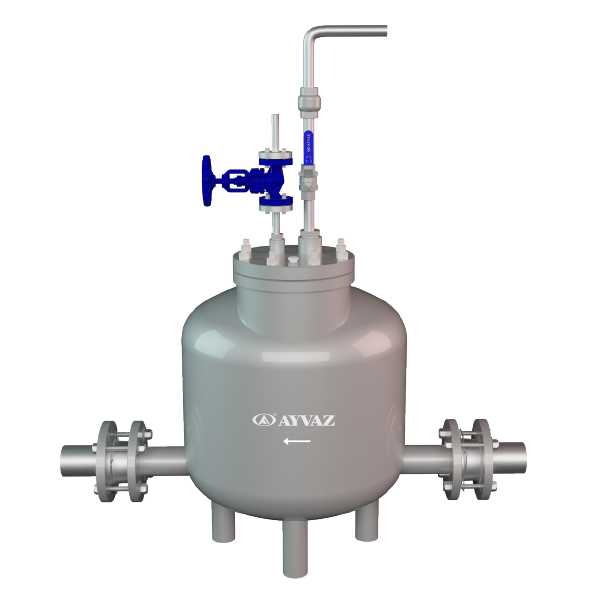

ACOM Mechanical Condensate Pump

Ayvaz ACOM Mechanical Condensate Pump is designed for the correct transfer of condensate and energy saving. Saturated steam or compressed air can be used as propellant in the pump. ACOM increases efficiency especially when used in stall situations where condensate discharge is impossible. It can also be supplied as a condensate pump station upon request. There are two disco check valves on the product.

WORKING CONDITIONS

Working Temperature: +10/+200 °C

Max. Condensate discharge:

10.000 kg/h

Max Inlet Pressure: 8 bar

Connection: Flanged

Size: DN50

Where is Condensate Pump Used in Processes?

• Temperature control valves (Pneumatic-electric actuator, thermostatic etc.) in temperature control processes

• In cases where the back pressure is high at the steam trap outlet

• In cases where the distance between steam trap and condensate tank is long

• In Stall situations

Problems That May Occur When Condensate Pump Is Not Used

• Corrosion

• Product deterioration due to thermal fluctuations in the heated product

• Thermal water hammer

• Loss of production due to heating inefficiency per unit time

Advantages

• Thanks to the return condensate, savings are made in boiler feed water and natural gas consumption.

• Heat exchanger and trap failures that may occur with water hammer are prevented.

• There is a decrease in the amount of chemicals fed for the water.

• Since blow downs will be reduced, there will be savings in fuel and water.

• Less energy consumption compared to electric pumps.

Downloads

If you need more documents, please drop us a message.