- Corporate

- Products

- Expansion Joints

- Flexible Metal Hoses

- Level Controllers

- Steam Equipment

- Valves

- Globe Valves

- Bellow Sealed Stop Valves

- Gate Valves

- Dismantling Joint

- Check Valves

- Ball Valves

- Butterfly Valves

- Actuators and Worm Gears

- Strainers

- Balancing Valves

- Pressure Reducing Valve

- SCHNEIDER Manometer Valves

- FCU On-Off Valves

- Solenoid Valves

- Earthquake Valves

- Hydraulic Control Valves

- Safety Valves

- Water Hammer Absorber

- Vacuum Lifters

- Insulation Products

- Fire Fighting Equipment

- Separators

- Certificates

- Publications

- Gallery

- Contact

- + Language

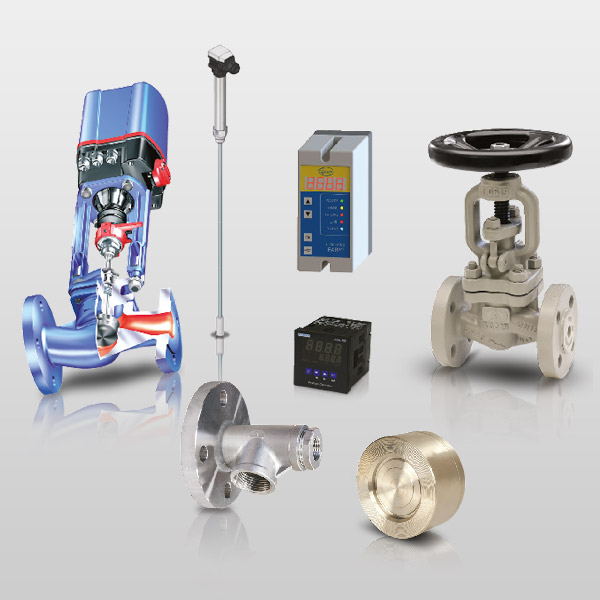

Condensate Pollution Control System

Condensate Pollution Control System

In order for a steam installation to work efficiently, the condensate which is going to the boiler feed tank must be in

maximum quantity and clean.

Any drilling of the heating coil or plate in the steam lines causes the heated fluid to mix into the condensate water. Polluted condensate will cause accumulation of sediments on the heating surfaces, corrosion and, more importantly, contamination of the boiler feedwater will lead to a reduction in boiler life, as well as a decrease in capacity efficiency. For this reason, the pollution we may occur in the condensate that must be detected immediately.

Working Principle:

This system, which is located at the entrance of the condensate tank, continuously measures the electrical conductivity of the condensate water. The conductivity measurement probe value is transmitted at the system control value. The controller compares the set conductivity value with the set value. When the set value is exceeded, the discharge valve opens and the condensate is discharged.

When the electric conductivity value is lower than the set value, the discharge valve closes and the condensate tank line is opened. It is sent to the condensate tank.

Since the electrical conductivity varies with temperature, the conductivity probe used in the system must be able to measure the conductivity at the temperature together with the conductivity so that the conductivity of the condensate at every temperature can be measured accurately.

Product Brochure

Click here to download the brochure of Condensate Pollution Control System

Other Products in this Product Group

PRODUCT SEARCH

NEW PRODUCTS

CUSTOMER SATISFACTION SURVEY

- Click HERE to join our customer satisfaction survey!