Hygenic Expansion Joints (Food & Beverage)

As raw material and energy cost rise, asset utilization within food & beverage plants become even more crucial. Many food processors still operate clean in place systems with little automation, relying on a purely timing-based process and manual verification.

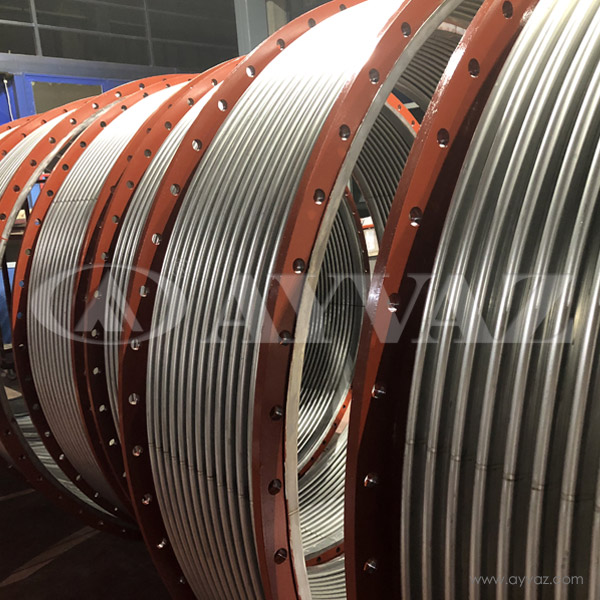

This cleaning operation is the heart of pipeline creation of the food and beverage sector and the expansion joints must be produced in special way to be cleaned easily which must have smooth welding and convolution surfaces. Expansion joint is the pocket-free design with drain characteristics – an indispensable feature for optimal cleaning in the CIP/SIP method.

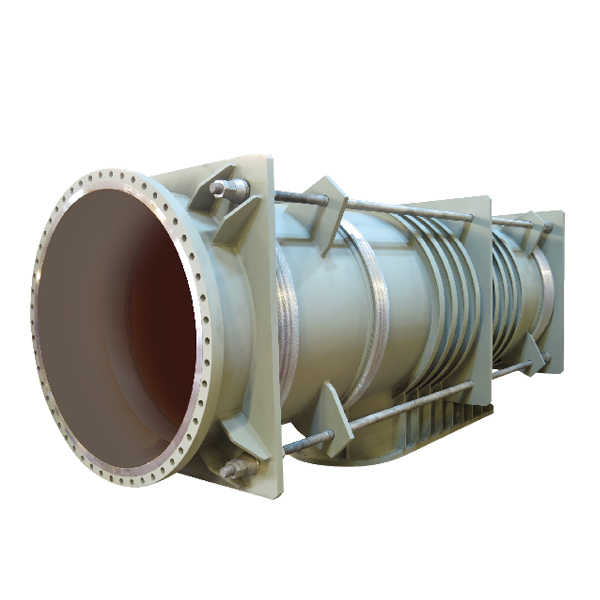

BELLOWS DESIGN

Expansion joints are used to compensate for thermal stress in pipe systems resulting from thermal expansion. They are especially suitable for valve matrices and fixed process pipe systems. They are ideally suited to hygienic and aseptic process operations. Applications include the dairy, beverage and food industries as well as the pharmaceutical, fine chemical, biotechnological and cosmetic industries. Expansion joints must meet both demands for cleanliness and flexibility. This is due to the most appropriate height of the convolutions of the bellow combined with a optimum distance between these convolutions. With this construction, optimum turbulence between each convolution is achieved which cleans the convolutions. The bellow geometry and the cleaning ability of the expansion joint is tested and verified.

Bellows of expansion joints are designed according to EJMA 10 code. For high pressure applications multi layered bellows with reinforcing rings. According to the requested features like type of transported media, spring rate values (axial, lateral, angular) or operation temperature, pressure & life cycle bellows material could be customized.

CONSTRUCTION

Expansion Joints are the parts of pip¬ing system of pressurized equip¬ment. In this respect construction of the expansion joints are designed and produced according to European pressurized equipment directive (PED 2014/68/EU) as well as American Nation¬al Standard for piping process ASME Section VIII Div 1&2, ASME B 31.3.

All components of the expansion joints like, pipes, caps, flanges, tie rods etc… are checked by piping stress ana¬lysis thus enable us to se¬lect material type & thickness accord¬ing to permissible stress values

GENERAL CAPABILITY RANGE FOR AYVAZ EXPANSION JOINTS

• Dimension: DN 15-6000

• Design pressure: Up to 150 bar (de¬pending on the diameter and tem¬perature)

• Lifting capacity: Up to 16 ton

TEST&CERTIFICATION

• Expansion Joints are the parts of piping system of pressurized equipment in this respect construction of the expansion joints are designed and produced according to PED 2014/68/EU&ASME U Stamp-U2 Stamp.

• Expansion joints are exposed to hydrostatic pressure at 1,5 times of design pressure.

• For full vacuum applications, vacuum test at 760 Hg/mm is also applicable.

• Additionally, gas leakage detection with helium is advised for proper tightness.